Safety Management: Fuel Starvation Due to Fuel Selector Condition

The following is an Aviation Safety Information Letter from the Transportation Safety Board of Canada (TSB)

On September 12, 2006, a privately operated Piper Cherokee PA-28-180 was in the circuit pattern for Runway 06R at the Montréal/St-Hubert, Que., airport. On base leg, at about 700 ft above ground level (AGL) and prior to landing, the pilot changed fuel tanks and selected the electric fuel pump to “ON” in accordance with the aircraft approach checklist. After a few seconds, the engine lost power. The pilot elected to turn off all electrical switches and execute a forced landing into a busy intersection. On final approach for the forced landing, the aircraft vertical stabilizer struck a telephone pole retaining wire, the right wing struck a vehicle, and the aircraft flipped over, striking three more vehicles before coming to rest. The vehicle occupants, pilot, and aircraft passenger sustained minor injuries. The TSB classified this accident as a Class 5 occurrence (A06Q0160).

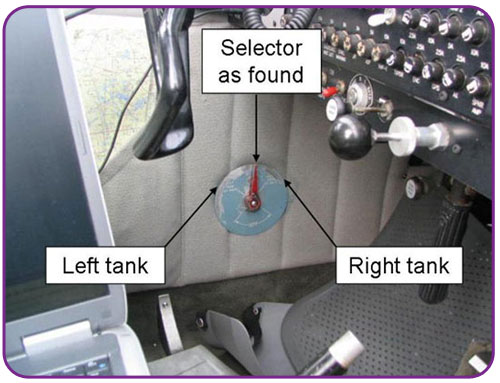

When the aircraft was recovered, the fuel selector was found positioned midway between the right and left fuel-tank selection positions. Testing of the fuel system with the engine in the accident aircraft running revealed that, by positioning the fuel selector in the midway position, the fuel flow to the engine was reduced to a fuel starvation state, followed by engine stoppage. Examination of the fuel system revealed no anomalies, with the exception of the fuel selector. The fuel selector was very difficult to move, and the detent positions were barely perceptible. The condition of the fuel selector valve assembly was consistent with a component that was not maintained in accordance with the manufacturer’s maintenance recommendations.

The fuel selector valve installed in the accident aircraft is a three-position type valve. An integral part of the valve is a tapered plug cock. This tapered plug cock, unless properly lubricated, is subject to binding or “freezing” caused by fuel coming in contact with the plug cock and gradually dissolving the film of lubricant, by the presence of foreign material, or by hardened or congealed lubricants, usually of the wrong type.

Fuel selector, as found

On June 5, 1972, Piper Aircraft Corporation issued Service Bulletin (SB) No. 355, titled Fuel Selector Valve Lubrication. SB No. 355 is applicable to Piper aircraft model PA-28-180 (serial numbers 28-1 to 28-7105179 inclusive), as well as to other small Piper aircraft. The primary objective of this SB is to ensure that the fuel selector valve is periodically and properly inspected and lubricated. The compliance time was within 10 hr of operation of the effective date indicated on the SB. The inspection/maintenance provisions of this SB were to be repeated at: each 100-hr interval, until the aircraft reached 400 hr of operation; then every additional 400 hr of operation or annually, whichever occurred first; or whenever the fuel selector valve was difficult to operate. This SB had not been completed on the occurrence aircraft, nor was the owner aware of its existence.

In Canada, owners of small, non-commercially operated aircraft may use the maintenance schedule provided by Transport Canada (TC) in Canadian Aviation Regulation (CAR) 625, Appendix B, Part 1 and Appendix C. Alternatively, owners could use the aircraft manufacturer’s maintenance checklist, if available, provided that this checklist includes at least all the applicable items listed in CAR 625. The tasks listed in the TC maintenance schedule are described only in general terms; whereas, the maintenance checklist produced by the manufacturer is detailed and includes references to the applicable service letters and SB produced by the manufacturer. The occurrence aircraft was maintained in accordance with the CAR 625 maintenance schedule.

The CARs clearly state that the maintenance of an aircraft is the responsibility of the owner. Therefore, should owners choose to use the less-detailed maintenance schedule in CAR 625 to maintain their aircraft, they are still responsible for developing an appropriate checklist for use with the maintenance schedule, and for being aware of any additional maintenance items such as out-of-phase items, service letters, SB or Airworthiness Directives (AD) that may apply to their aircraft.

Source: Transport Canada Safety Letter Issue 3, 2010

.jpg)